Boris Cergic (AT), Valentin Rezsnyak (AT)

u19 winner: Honorary Mention

The FotoFlex cell is a completely new development that, thanks to its low production costs, can make environmentally friendly electricity affordable and attractive for all humankind. This could be called a textile form of climate protection for everybody!

Dr. Michael Grätzel is the key developer of a new type of solar cell, the dye-sensitized solar cell, which is much cheaper to produce than conventional, silicon-based solar cells and works better, especially in dim light. This is a photovoltaic cell based on dyes. The targeted application of conductive layers, separators and electrolytes makes it possible to produce a photovoltaic cell that functions exactly like a conventional cell based on doped silicon but without its major disadvantage – serving as its electrodes are glass plates that have been made conductive, but this also makes the cells relatively rigid when it comes to applications, and thus limits their flexibility.

Due to the rapidly growing demand for decentralized energy sources and the human population growth that parallels it, making available cheap, clean, electrical energy has become one of our generation’s biggest challenges. Since it’s foreseeable that we’re approaching the end of conventional methods of electrical production, alternative forms of energy have to be our future.

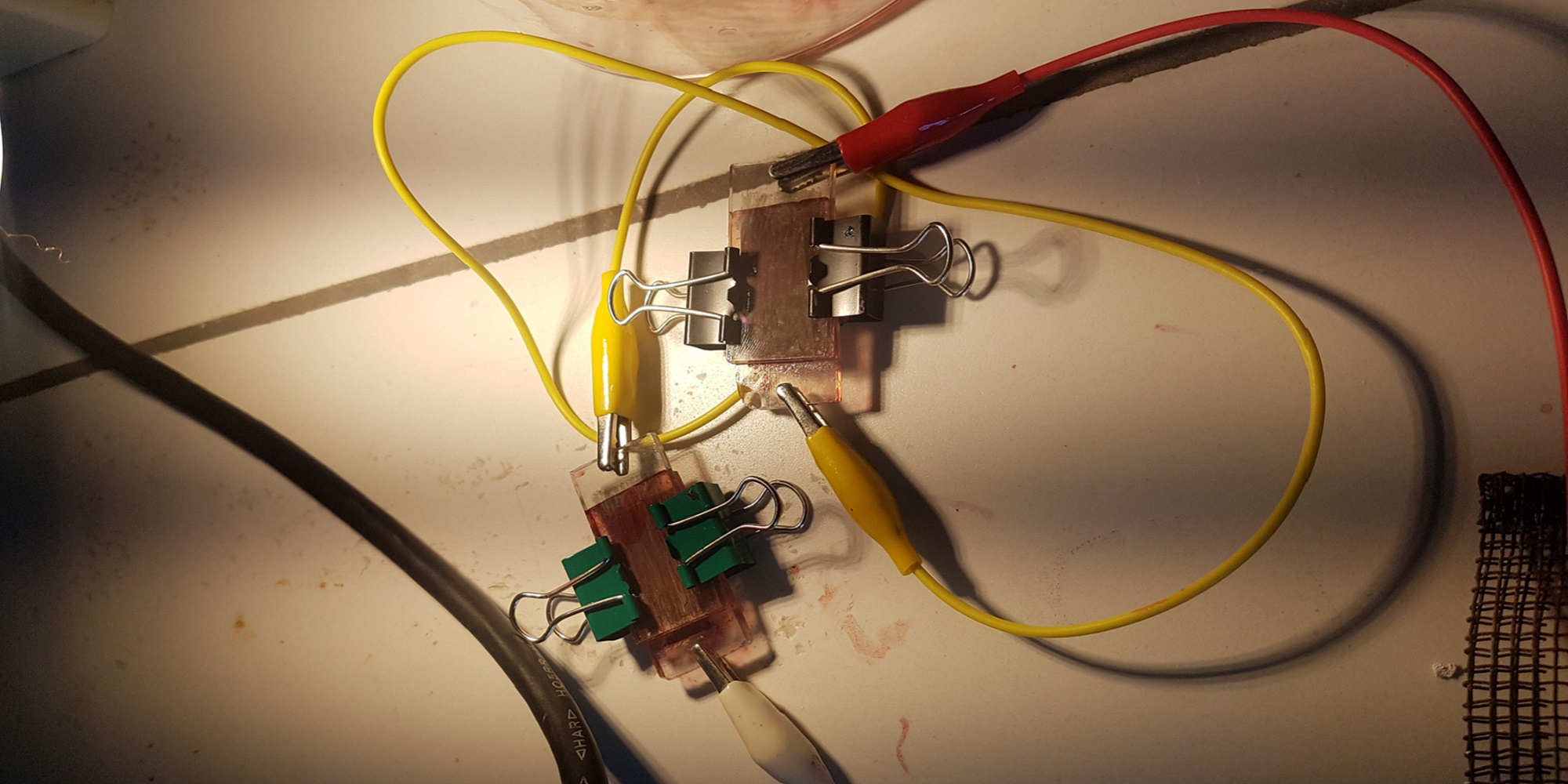

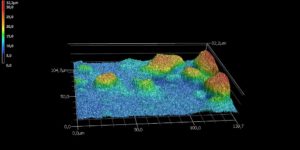

For modern applications, a solution has been developed that is based on natural dyes and is also flexible both with respect to form and application. By replacing some of the materials used in Dr. Grätzel’s invention, we have transformed a rigid, fragile cell into a robust, flexible one. Precision manufacturing as well as expertise in textile chemistry and material science that is the result of intensive basic research play important roles in this process. In Grätzel’s dye-sensitized solar cell, all essential components are installed between two TCO glass plates. In the cell that we have developed, the glass has been replaced by carbon fiber, which is electrically conductive as well as robust and flexible. This makes it suitable for a broad spectrum of applications. Thanks to the high adsorption capacity of the individual fibers’ large surface, the titanium dioxide to which the dye is applied adheres very well.

The FotoFlex project team is Boris Cergic and Valentin Rezsnyak. Boris likes to play American football in his spare time; Valentin gets his kicks playing ice hockey. This interest in sport as a welcome respite from everyday life is something they have always had in common. They became acquainted at Dornbirn Technical School, where they majored in Textile Chemistry and Chemical Production & Environmental Technology: “This has enabled us to optimally deal with textile chemistry problems as well as the environmental aspects of the project.”

credits: Boris Cergic (AT), Valentin Rezsnyak (AT)