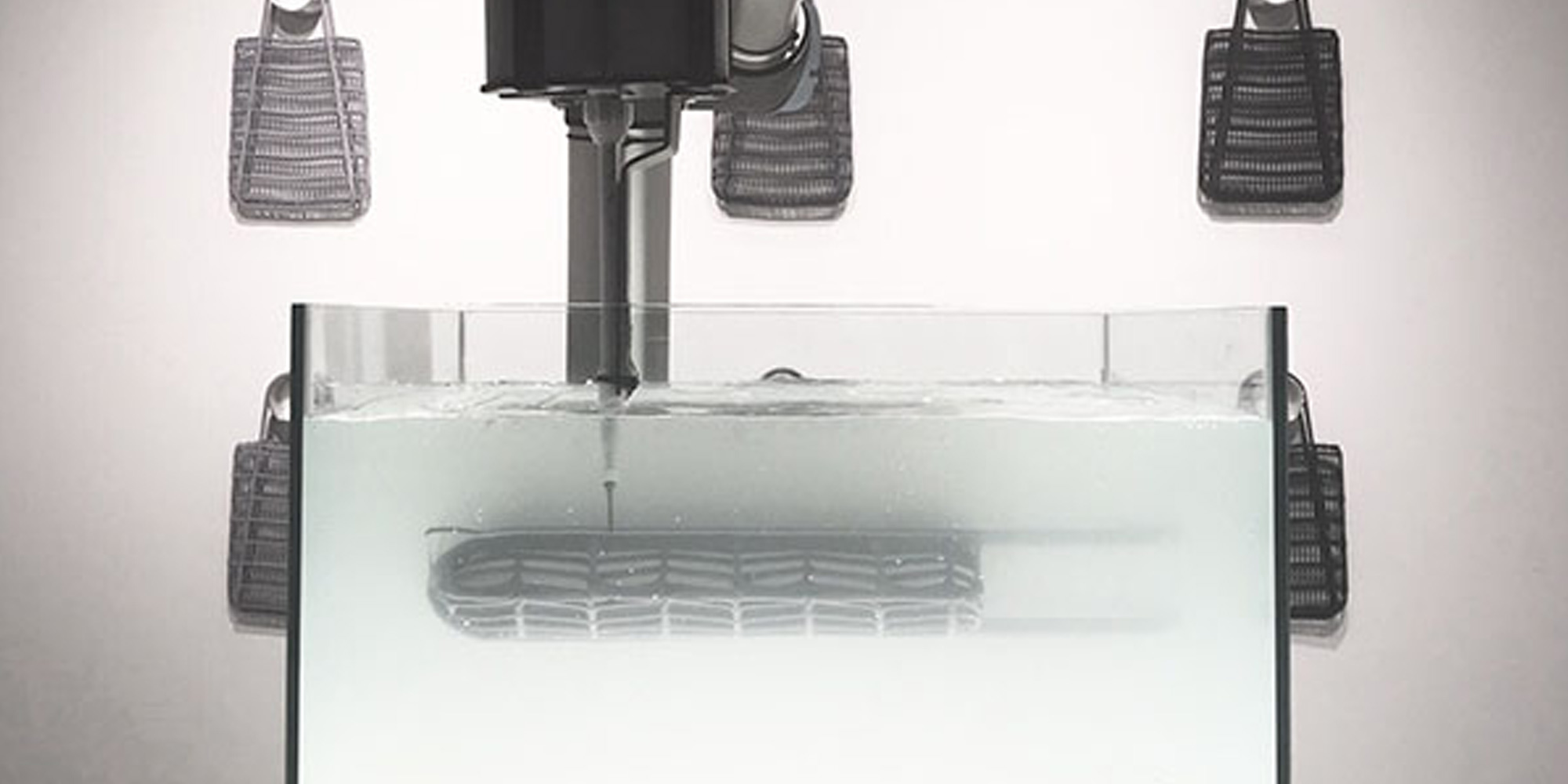

MIT’s Self-Assembly Laboratory, in collaboration with BMW Design Department, are developing programmable material technologies that self-transform, adapt and morph from one state to another. This new commission explores a silicone printed object that changes shape depending on the amount of air pressure in the system. The flexible silicone structure is the first example of a fully printed inflatable that can be customized to any size or shape. The pneumatic controls in the system allow the printed structure to transform into a variety of shapes and functions. This adaptive material technology points towards a future of transformable surfaces for adaptive human comfort, cushioning and impact performance.

Printed Silicone

Self-Assembly Lab Team: Bjorn Sparrman, Shokofeh Darbari, Rami Rustom, Maggie Hughes,Schendy Kernizan, Jared Laucks & Skylar Tibbits

BMW Team: Sophie Richter, Akos Stegmar