STARTS PRIZE’18 – Nomination

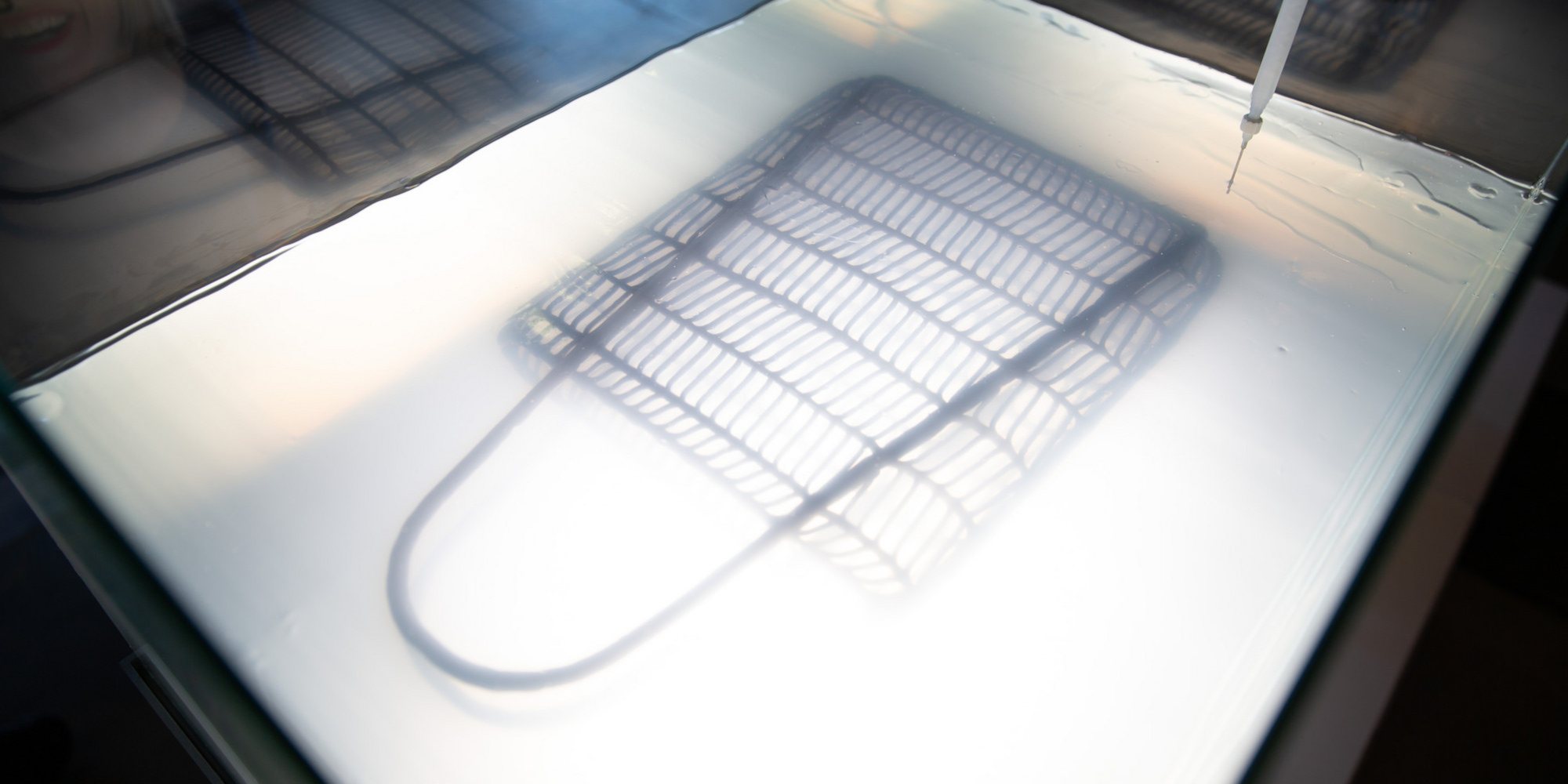

In collaboration with Steelcase, we are presenting a new experimental process called Rapid Liquid Printing, a breakthrough 3D printing technology. Rapid Liquid Printing physically draws in 3D space within a gel suspension, and enables the creation of large-scale, customized products made of real-world materials. Compared with other techniques we believe this is the first development to combine industrial materials with extremely fast print speeds in a precisely controlled process to yield large-scale products.

3D printing hasn’t taken off as a mainstream manufacturing process for three main reasons: 1) it’s too slow compared to conventional processes like injection molding, casting, milling, etc. 2) it’s limited by scale—although it’s good for creating small components, it’s not possible to produce large scale objects and 3) the materials are typically low-quality compared to industrial materials. Rapid Liquid Printing addresses all of these limitations: it is incredibly fast (producing structures in a matter of minutes), designed for large-scale products (you can print an entire piece of furniture), and uses real-world, industrial-grade materials.

Credits:

Self-Assembly Lab Team:

Kate Hajash, Bjorn Sparrman, Schendy Kernizan, Jared Laucks & Skylar Tibbits

Steelcase Team:

Yuka Hiyoshi, Rob Poel, Markus McKenna, Paul Noll, Sharon Tracy, Chris Norman & Charlie Forslund

Websites:

- https://selfassemblylab.mit.edu/liquid-printed-products

- https://starts-prize.aec.at/

- https://www.starts.eu/