Airbus, APWorks, Autodesk, The Living

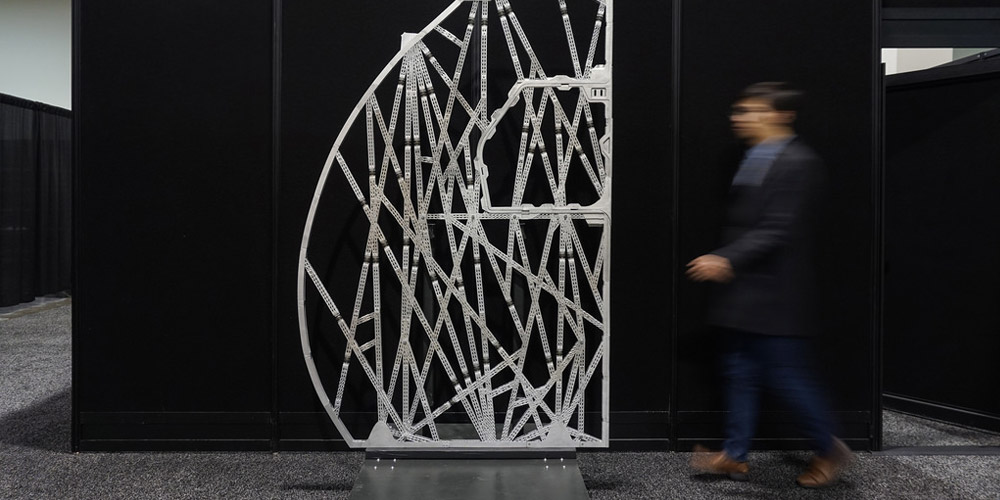

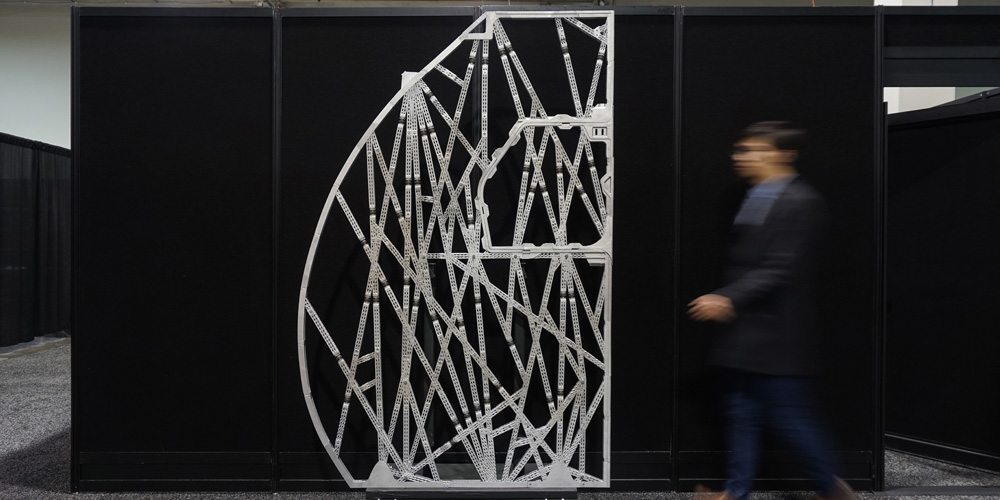

The Bionic Partition is the world’s largest metal 3D printed airplane component. The partition is a dividing wall between the seating area and galley of a plane, and it is a challenging component to design because it must include a cutout for emergency stretcher access and it must hold a fold-down seat for cabin attendants. The new Bionic Partition created through a pioneering combination of generative design, 3D printing, and advanced material is almost 50% lighter than current designs, and it is also stronger. This weight savings translates to fuel savings and carbon reduction. The final design illustrates a novel use of “bio computation,” and it demonstrates an ultra-high-performance result beyond typical engineering rules of thumb. The Bionic Partition is currently undergoing 16G crash testing as part of the process for certification and integration into the current fleet of A320 planes.

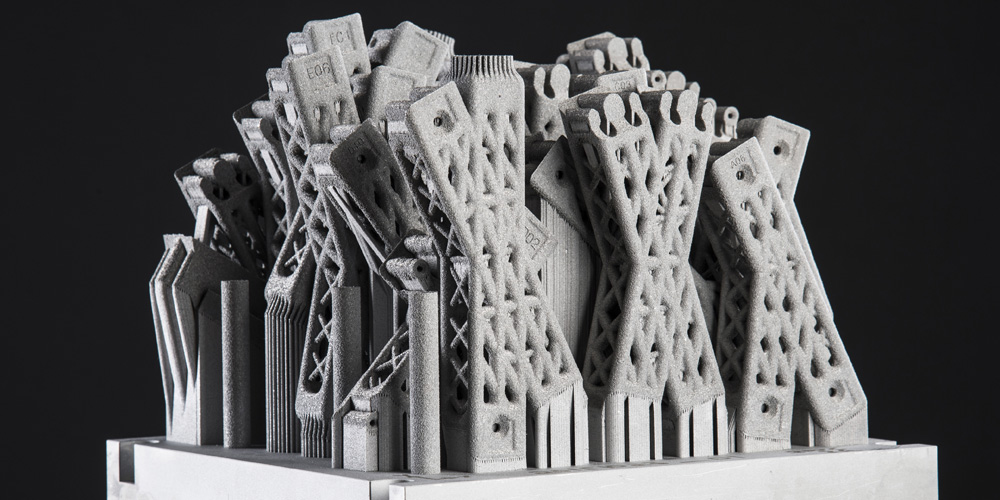

When slime mold grows, it creates a complex 2D network that is both efficient and redundant. It is efficient because it connects a given set of dots (food) with a minimal amount of lines. And it is redundant because each dot touches at least two lines so if any line is removed, the dots remain connected in the network.

We developed an algorithm that uses the “biological algorithm” of slime mold to link critical connection points in an airplane partition. Then we ran a process of bio computation that generates, evaluates, and evolves tens of thousands of design options.

Combining our custom techniques of data science and bio computation, we can derive results that are both high performing and unexpected. The process is not about achieving cold-blooded efficiency. Rather it is about expanding our creativity.

The Bionic Partition is pushing the limits of several technologies, but it is on track for a real industry application this year. When applied to all A320 planes on backorder, this new design approach could save up to one million metric tons of carbon emissions per year.

The Living, an Autodesk Studio (US), Airbus (DE), Autodesk (US), and APWorks (DE)

Airbus, a division of Airbus Group, is the global leading commercial aircraft manufacturer with the most modern and efficient family of airliners. APWorks specializes in metallic 3D printing and covers the entire value chain, from optimized product design, to choice of materials, to qualified serial production. Autodesk helps people imagine, design and create a better world. The Living applies generative design, biology, and new materials to real built projects in the context of technology, culture, and the environment.

Project credits

Airbus, APWorks, Autodesk, The Living

BIONIC PARTITION STEERING COMMITTEE

Ingo Wuggetzer, Airbus

Jeff Kowalski, Autodesk

Stefan List, Airbus

Gonzalo Martinez, Autodesk

PROJECT DIRECTORS

Bastian Schaefer, Airbus

David Benjamin, The Living

THE LIVING

Design lead: Danil Nagy

Simulation lead: Damon Lau

Optimization lead: Dale Zhao

Design team: John Locke, Ray Wang, Jim Stoddart, Lorenzo Villaggi

AIRBUS

Project sponsors: Joerg Schuler, Peter Sander, Jens Telgkamp

Advanced design: Tobias Meyer

Specific design concepts: Markus Hollermann, Benjamin Doehrmann, Maximillian Marchinowski, Philippe Videau

Stress evaluation: Martial Somda, Thayfun Guelle

Business case: Stefan Holst, Jan Gottemeier

Machining: Carsten Stender

Post production and assembly: Ana Dulce de Meneses Machado Silva, Hendrick Doehrmann

AUTODESK

Autodesk Dynamo technical consultants: Ian Keough, Michael Kirschner, Matt Jezyk

Project “Dreamcatcher” and Project “Saturn” technical consultants: Huaijun Wu, Francesco Iorio

Simulation advising: Nanda Santhanam, Ian Pendlebury

MeshMixer technical consultant: Ryan Schmidt

Autodesk Simulation Mechanical finite element consultant: Sualp Ozel

Autodesk Robot Structural Analysis automation consultant: Emmanuel Weyermann

Autodesk SimStudio finite element consultant: Jon Den Hartog

Autodesk Nastran simulation consultants: Mitch Muncy, David Weinberg

APWORKS

Project coordination: Joachim Zettler

3D print: Felix Rothe, Andreas Nick

Machining: Chris Seiffert

Video production: Angela Gruenewald

CONCEPT LASER / ROBERT HOFMANN GmbH

Project coordination: Jens Henzler, Peter Mischke

3D print: Michael Dinkel, Peter Appel

LANTAL

Project coordination: Hanspeter Baumgartner

Development and production: Jacqueline Schwendele

3D ICOM

Project coordination: Karin Sittner

Production: Michael Loch, Galina Ivancenko, Martin Gosch

PREMIUM AEROTEC

Machining: Thorsten Pape, Joerg Lueers, Holger Gerriets